“The Michel BRAS” series are based upon finding the perfect balance between the latest technology and the craftsmanship of experienced artisans.

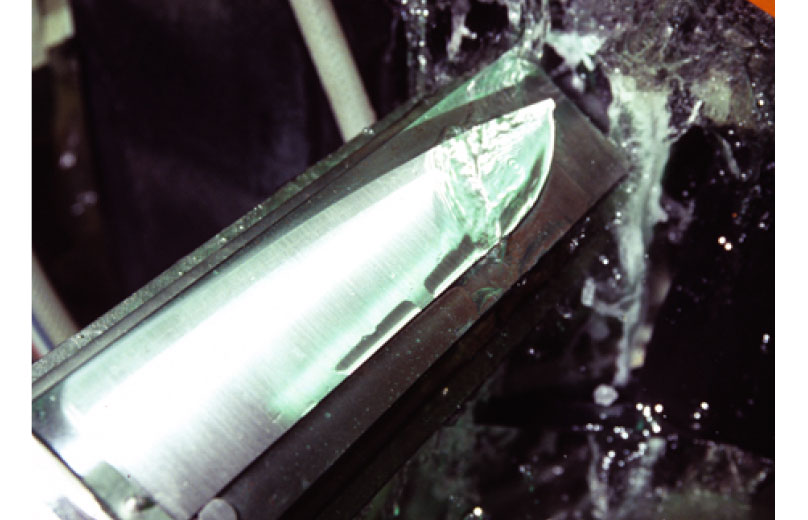

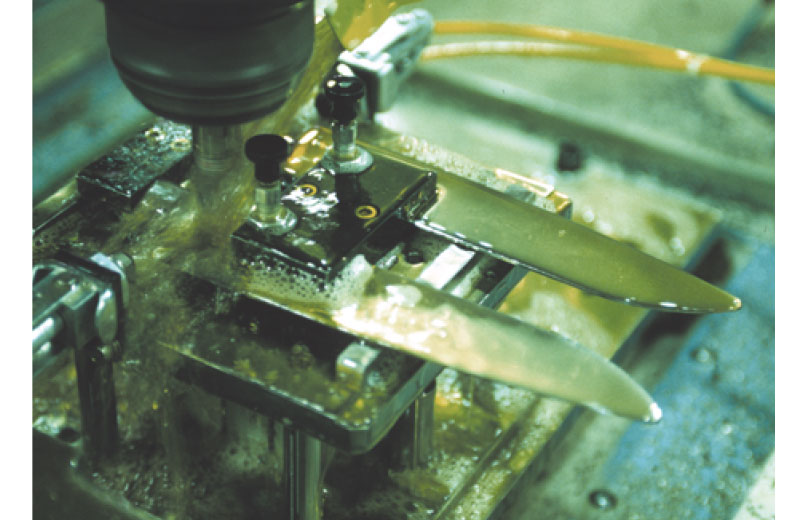

First step to a knife: grinding and polishing

A blade of equal thickness is ground and polished so that it takes the shape of a knife from the tip all the way along the blunt upper edge. Next, to polish the surface, pure water is poured over to the blade, while a cylindrical whetstone rotating at high speed grinds it into shape. A second polishing is done by hand to finish what will be a beautiful blade.

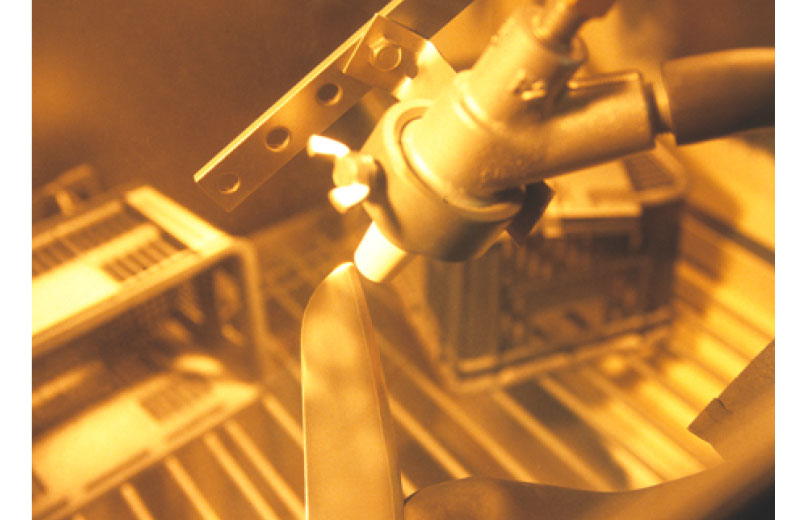

Soldering the “bolster”, the base that supports the blade

The bolster is the core of the knife, and serves to bind the blade and the handle together. It must be soldered on and then polished after the superfluous parts have been eliminated. The angle and shape of each bolster are finished differently according to the particular qualities of each of the ten varieties of blades and handles.

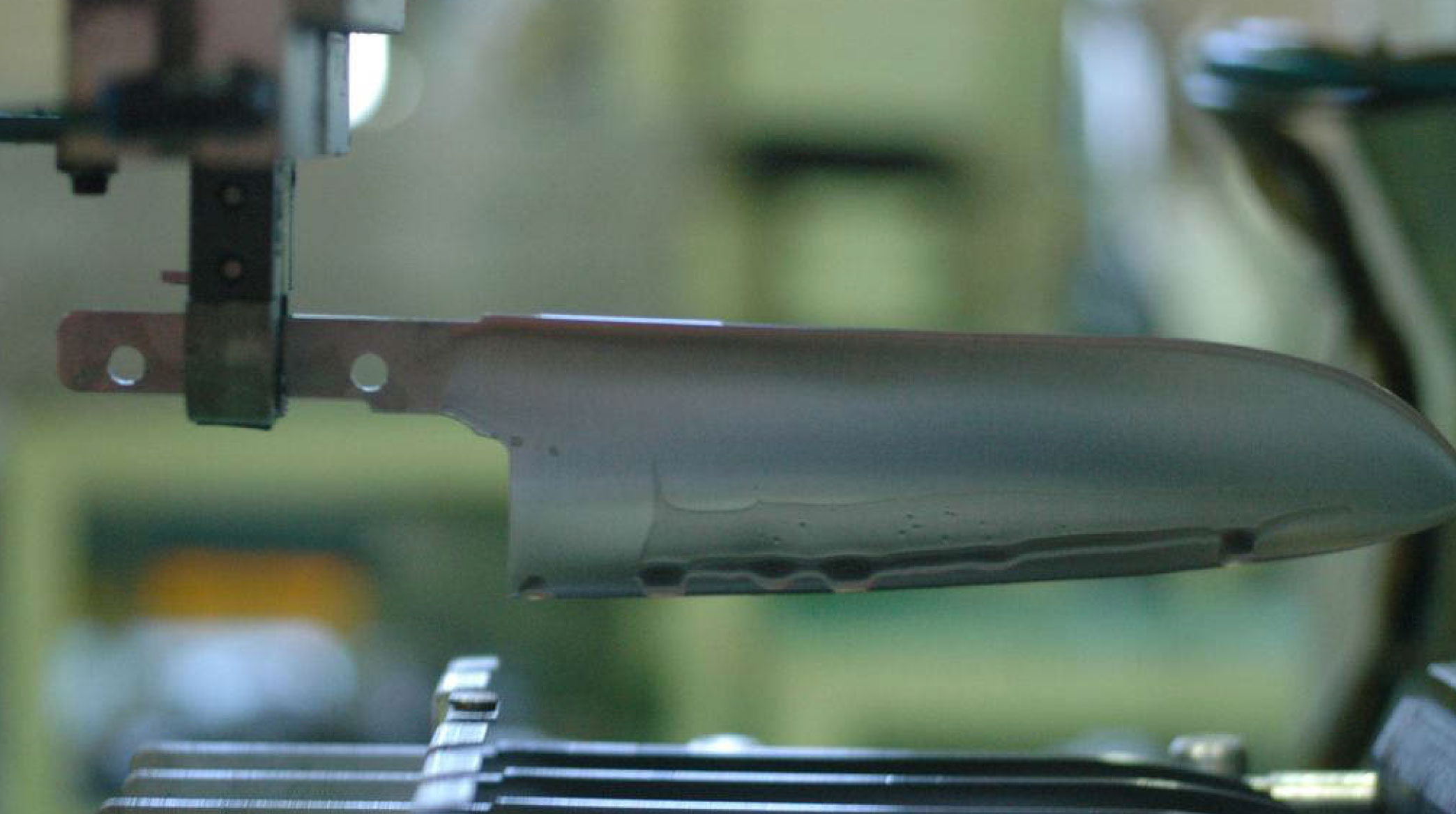

Sandblasting for sophistication

The unusual matte appearance of the blade is achieved by a method called “shotblast”. Very fine glass beads are blown against the blade at extremely high pressure. The result depends upon the precise hand-movements of the artisan as he holds the blade during this process.

Assemblage by hand

The blade and the handle, the handle and the metal end piece are all assembled by hand. The task that requires the most precision is the assemblage of the chestnut-shaped handle and the metal end piece. They are matched repeatedly until they fit together exactly.

Breathing life into the blade: the final process

The final sharpening yields the cutting edge suited to each knife’s individual different purpose. First comes water polishing, using a rotating whetstone onto which water is poured. Then, the blade undergoes a leather polishing using a strip of cow hide on another rotating cylinder. The combination of these two techniques results in a blade of exceptional sharpness and finesse. Skilled technicians watch the blades carefully to insure the process lasts only long enough to bring each blade to a state of perfection.

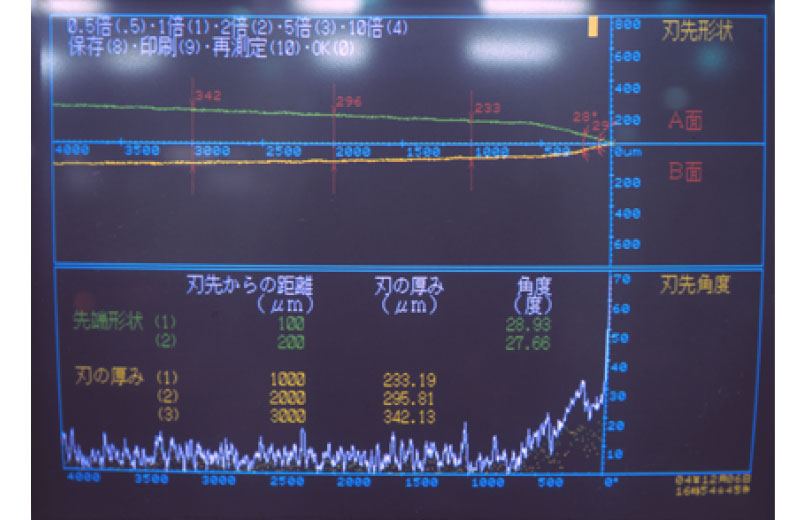

Quality controls measured in “μm”s

Strict quality control is maintained throughout the process, but there is also a final random check. Measurements of the shape, angle and thickness of each blade are input to a computer which verifies the data within a precision of a thousandth of a millimeter (μm ). There are additional checks made upon every element of each knife and its packaging prior to shipment.